Buying Technics Turntables

Buying Technics Turntables

When buying Turntables just do this quick check list so you only pay for the deck and not for repairs. The arm is the part that gives most of the problems.

1. Look at condition of face plate Sweat marks on the right hand side of the turntable this mark gives you good indication of how old the deck is or how much action its had this mark is due to acid sweat mark which attacks the coating.

2. Check for movement in arm assembly by holding the head shell check for free play at bearing end and head shell end.

3. Set height of the arm to zero and look for a even height along the arm make sure that the head shell is not bent down . feel under the chrome arm pipe where the arm rest lock is and feel for any dints or ripples in pipe with your finger.

4. With the headshell on wind the counter weight on the arm around until you have the arm in the balanced position take the arm across the the center spindle making sure that the anti skate is set to 0 now turn the anti skate to 3 the arm should move back to the arm rest without no restriction if it stops at a certain point on platter the bearings are damaged and should be replaced the only way to use this deck without skipping is to loosen the top pivot point or stick bluetac and a 5 cent piece on head shell which you see allot check the pins inside where the head shell fits these gold connects cause lots of problems they should be clean and not pitted and make sure you use a original technical head shell.

5. Pitch control set pitch to center click with green light on quartz lock this means that when you press 45 or 33 the center dot on the platter stands still slowly slide the pitch control knob down and look at the platter dots and look for any fast take away movement from the green light is bad and makes it near impossible to mix quick jerking movement of the strobe light while sliding the control suggests that the pitch needs adjusting or replacing move the slide control to plus 6 and the bottom dots should stand still move the control knob to minus 3.3 and the top dot should stand still i often have people say to me that there turntables are not running at he same speed at say minus 3 and the pitch needs changing but there are lots of other reasons for different speeds off quartz lock position as the way the speed is controlled by resistance and voltage rather than quartz lock which uses 3 detector coils and the timing of quartz crystal to get exact speed spindle drag or drive magnet strength maybe stronger than the other deck I've even seen dust under platter causing drag and hair around spindle no oil or not having the deck level so take note.

6. Electronics check power knob for a clean click when turning on and off look at the brightness of the red led's in the strobe if they look dim or dip when the start stop button is depressed protection ics should be changed check pop up lamp (target lamp) look for a nice slow extension of lamp when pressed and that it lights up, check stop start button, check brake should stop and start half revolution from quartz lock. check 45/33 buttons make sure there not sticking.

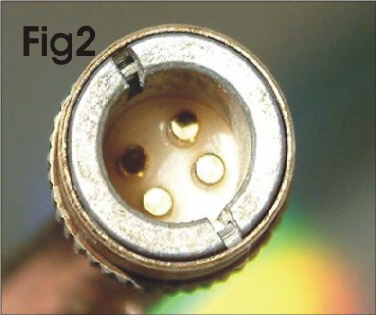

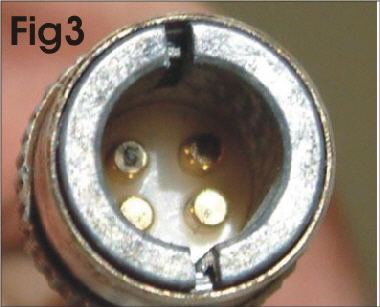

7. Contact points as seen in (fig2) notice how the pins have gone rusty this is due to the habit of licking the end of the head shell to get a good contact, yes it does work but the acid in your mouth and the presents of different metals and a electrical current cause electrolysis, if you use the original Technics head shell you will never have this problem but if the damage is done you will have to replace the pins always look for flat clean gold contacts as in fig 2. notice in fig3 that the top 2 pins are pitted the top 2 pins are the positive left and right channels from the coil on the cartridge these 2 pins carry the current to the mixer and are most susceptible to bad contact and damage.

8. overall check all the above and if you find these faults bring down the price knowing that they have to be replaced here is a price guide.

All prices are exchange and are fitted with the one up labour/service cost $99.00 Only available in Australia / Sydney and South Australia

Pivot Point Bearings $44.00

Pitch Fader $69.00

Chrome Arm Pipe $39.00

Pop up Lamp $18.00

Power Knob $34.00

Contact Pins $34.00 (for all 4pins 15 micron gold)

Protection ic's $7.00ea ( 3 units per deck)

Arm Rest Holder $18.00

Please Note: the arm is not normally available broke down like this, its sold by Technics as the whole arm assembly around the A$300.00 mark for that reason i have broke the arm down in to 4 main parts this keeps the cost down so you only pay for the part required.

For more information on service and outlets go to service outlet page in main menu, if you have any questions drop me a email and ill get back to you asap kevin@deckdoctor.com.au i hope this information helps you come back soon for more information and facts and fixes.